|

|

|

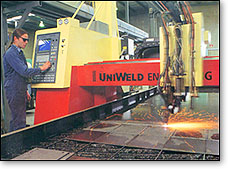

Fine plasma precision with leading-edge technology Fine plasma precision with leading-edge technology

With the purchase of a Farley Phoenix cutting system, Uniweld has become the first Australian company to install such a machine and be able to offer fine plasma cutting, a technology which has redefined precision profiling. |

|

The benefits of fine plasma cutting

- One tenth of normal cutting costs due to speed and larger sheet sizes that can be handled. Cutting speeds of up to 25 m/min on multiple parts are attainable.

- Laser quality output at plasma-cut costs.

- A reliable and affordable alternative to more expensive production methods such as punch presses, hard tooling, laser or water jet cutting.

- Reduced lead times and the need for downstream processing or fit-up.

- Greater precision and excellent, clean, 90° edges with no dross and a precise narrow kerf.

- Offers very exacting plasma cutting with an unsurpassed parts accuracy of ± 0.1mm and a repeatability of ± 0.05 mm.

- Allows the cutting of holes and shapes in aluminium 6 mm thick.

- Profiles plate from 1.6 - 12 mm thick.

|

|

And a whole lot more...

In addition to its plasma and fine plasma cutting capabilties, Uniweld also specialise in:

|

- punching

- oxy cutting

- guillotining

- CNC brake press forming

- general metal fabrication

- shearing

- MIG/TIG and ARC welding

- robot welding

- structural fabrication

|

This combination of equipment and facilities at Uniweld ensures that as much as possible is done for customers in-house.

|

|

|

|

|

|

|

Another website by

Copyright Internet Media Worldwide Pty Ltd 1997 |